Tips and tricks.

On this page you find some "Tips and Tricks" that's can help by modeling, scratchbuilding and mastermodelling.

For real, clean and nice modeling is it necessary that you use the right tools and material.

Use your expierence and fantasy !

"If you have information for this page, send it me by e-mail"

E-mail to Henk Timmerman / HenkofHolland

Click on the pictures

What do you need for modelling, scratchbuilding or mastermodelling:

Tools & Materials

- Graduated ruler

- Knife or hobby knifes

- Small scissors

- Pair of tweezers

- Hobby pliers

- Set of small key files

- Set of Watch screwdrawers

- Waterproof sandingpaper

- Electric Drill

- Set of small drills

- Cutting saws

- needles

- Signograph

- Pyrograph

- Magnifier

-------------------

Glue

- White Glue

- Cyanoacrylaat glue

- Universal glue

-------------------

Plastic card etc.

- Plastic Card

- Plastic Rod

- Plastic Tube

- Plastic strips

- Stencil

-------------------

Paint etc

- Airbrush

- Pencils

- Acrylic model paint

- Thinner

- plastic putty

- Milliput Epoxy Putty

-------------------

Others

- Spare parts

- Copper wire

- Metal wire

- Wine- or Tea-led

|

Plastic sheet, rods, tubes and strips etc:

Evergreen Scale Models", U.S.A.

The most of the plastic card, rod, tube and strip I use are from this manufacturer. All products are listed in a catalog. Ask in your modelshop for this products and/or catolog or take a look on the website from "Evergreen".

Evergreen Scale Models Website

Evergreen Scale Models Website

SlatersPlastiKard U.K.

A other producer of plastic sheets, rod and strips are "SlatersplastiKard"

SlatersPlastiKard Website (Railway Products)

SlatersPlastiKard Website (Railway Products)

In most of the modeling-shops you can found plastcis sheets from a unknown manufacturer, this sheets are most-time more cheaper.

Milliput the epoxy putty

Milliput Epoxy Putty Website

Milliput Epoxy Putty Website

There are 4 different putty variants/quality available.

Milliput products are available from most leading model/hobby shops and art and craft suppliers. Ask your shopholder for this product.

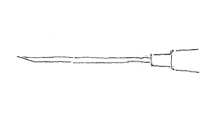

How to make towing-cables:

1.Take a part of electric cable

2.Cut off the rubber/plastic mantle and you become on this way a lot of very thin copper wire

3.Take some copper wire, so many as you need (5 is normal) and twist this with help from a hobby drill

4.Take some towingcable eyes, available in some plastic kits (I use the eyes from the Eastern-Express T34 kits. You can copy this eyes by casting.

5.Drill small holes into the end of the eyes.

6.Cut off the twisted cables on the lenght as you need.

7.Glue the cables with Cyanoacrylaat glue in the drilled holes

How to make tarpaulins, tilts etc.:

What you need:

paper handkerchief, white glue for wood or paper, water, metal shaft and a pencil.

1.I you want to make a tilt for a truck, make a frame from metal shaft and glue it with Cyanoacrylaat glue on his place.

2.Cut of a part of the paper handkerchief and glue it on the frame with a few Cyanoacrylaat glue.

3.coat the paper with white glue and let it dray 24 hours.

4.For the thickniss of the tilt or to make it stronger, repeat point 3 one or more times.

5.To make tarpaulins, canvas etc., use your fantasy.

Results:

How to make tarpaulins, tilts etc.: (by by Hakan & Erhan)

"MiniAfv" Blogspot

"MiniAfv" Blogspot

How to make a "braille scale" barbed wire (By Hakan Karli)

"MiniAfv" Blogspot

"MiniAfv" Blogspot

How to make snow effect (By Hakan Karli)

"MiniAfv" Blogspot

"MiniAfv" Blogspot

How to make braille scale palm (by Levent Inceayan)

"MiniAfv" Blogspot

"MiniAfv" Blogspot

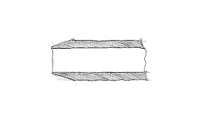

How to make rivets(1) - How to made "Punch and Die"

by Alexandru Giersch, mastermodelmaker from Roumania:

Dear modellers:

Enclosed my own tools for making rivets of all kind. You'll see, it's a hand made "punch & die".

First you have my main part of the tool, a lead plate and some small plastic plates. Most use plastic thickness is 0.13 mm.

Then you'll see the tools - syringe needles cuted short. The needle and the wire necessary to take out the rivet. And you see how I'm doing.

I use to pose the rivets a very sharp needle. What I can tell you is that I make 5-10 rivets one after the other before to take them out.

The main inconvenience is that my rivets are plate, not semi rounds. But this could be solved with a very fine sand paper.

"As you know from your own experience, everyone get use it self with the tools or methods that he use. All modellers are, I guess, like that. I like to have a compromise between good and cheap. You'll tell me

that's impossible most of time. Here we could say that the modeller's hand and brain makes the tool good."

Alexandru Giersch

For information and questions to Alexandru Giersch use email address below:

E-mail to Alexandru Giersch "delete in email address - (stopspam)"

Drawings - information:

pic. 1 - initial syringe needle, before cutting

pic. 2 - syringe needle after cutting

pic. 3 - syringe needle after cutting, big size drawing

pic. 4 - syringe needle sharpened

pic. 5 - to obtain rivets you have to press the needle on the plastic sheet. For a better result

and also to protect the needle's sharpness, I suggest to use as base a plate made from lead

pic. 6 - remove the plastic rivet with a steel wire close to the inner needle's diameter

Photo-information:

photo 1 - initial syringe needle

photo 2 - disks to use for cutting

photo 3 - before cutting, the disk is in the drilling machine

photo 4 - after cutting

photo 5 & 6 - after cutting and during sharpening, is better, from time to time, to clean the interior of the syringe needle using one sharp needle

photo 7 & 8 - 2 steps sharpening : 1 - using a file and 2 - using different sand paper

photo 9 - to remove the plastic rivets I use a steel wire or another syringe needle, appropriate to the inner diameter of the punch.

Photo-information - "How you have to do it!":

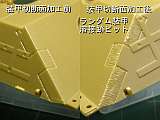

How to make rivets(2)

With help from a special "Universal Rivet Tool" tool

The tool is made and available by G.W. Models, 2 Talltrees, Penstone Park, Lancing, West Sussex, BN15 9AG, UK

No website or e-mail address available!!

The price of the tool is maybe not cheap but the tool is for mastermakers very helpfull. With help of the levers and after some experience you made all rivets in same size, in a right line and on same distance.

Included by the tool are "Punch and Die" in different sizes that made that the tool is usable for rivets in the 2mm, 4mm and 7 mm scale, (usable in plastic, thin copper- and thin aluminium plate)

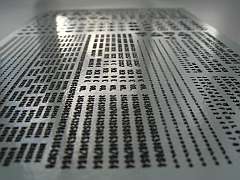

How to make rivets and casting symbols(3)

With help from "Archer Transfers"

Recommended

Surface Details - Rivets/Screws - Armor casting Symbols and Markings

A lot of plastic and resin models in the "Braille Scale" size have a lack on details as rivets/screws and armor casting symbols and an upgrade is needed.

To become correct and acceptable rivets etc. is mosttimes a nightmare for a lot of modellers. There are many tools available as "Punch and Die's" and

other instruments. There are also a lot of tips using glue, hot needle, very thin sprue etc.

It seems that "Archer Transfers" has made possible the simplest way to become nice rivets etc. They has made transfers were the symbols are in relief.

For more information see below:

AR88001 - Surface Details #1 - Rivets/Screws .008"(.20mm) - 011"(.28mm) - 014"(.36mm) Diameter

The set comes in a plastic bag with label.

The size of the transfer is 7.5 x 11 cm and contains Rivets/Screws in different sizes.

The transfer is usable for various scales (braille Scale).

Instructionsheet is included.

Read instructionsheet careful.

An entirely new technology molds three dimensional details onto clear decal film that is applied UNDER the paint to add missing details

or replace details lost by sanding. ~~Apply like water slide decals~~

.

.

.

AR88007 - Surface Details #7 - Armor casting symbols and Markings

The set comes in a plastic bag with label.

The size of the transfer is 7.5 x 11 cm and contains Armor casting symbols and markings.

The transfer is usable for various scales (braille Scale).

Instructionsheet is included.

Read instructionsheet careful.

An entirely new technology molds three dimensional details onto clear decal film that is applied UNDER the paint to add missing details or

replace details lost by sanding. ~~Apply like water slide decals~~

.

.

.

For more information and ordering:

Website Archer-Transfers

Website Archer-Transfers

How to make rivets(4)

With help from "MicroMark Transfers"

Recommended

Sheet 84985 - HO Scale Decals With Raised 3D Rivets And Other Surface Details - (contains 2 sheets - Size A4 6 x 10,5 inch - 21 x 28cm) - (HO = 1/87)

Sheet 84987 - O Scale Decals With Raised 3D Rivets And Other Surface Details - (contains 2 sheets - Size A5 6 x 9 inch - 14,8 x 21cm) - (O = 1/48)

.

.

For more information and ordering:

Website MicroMark

Website MicroMark

Comperison MicroMark (O-scale) rivet sheet with Archer Transfer 88001 - (YouTube)

Comperison MicroMark (O-scale) rivet sheet with Archer Transfer 88001 - (YouTube)

How to use decal instructions

How to use decal instructions

Warning Note: shipping by UPS, another way is not possible!

The price of the sheets is on the moment (2019) around 16,70 Euro

Shipping to Netherlands (Europe) by UPS

1 set 16,70 Euro, no tax, shipping 28,20 Euro, totalprice 44,90 Euro

2 sets 33,39, tax 11,70, shipping 28,79, total price 73,88 Euro

3 sets 50,09, tax 15,88, shipping 28,94, total price 93,91 Euro

It's looks me that shipping as parcel by UPS is very expensive!!

My advice, if you want to order try to find a contact in the US that will order for you, cost of shipping inside the US + cost of shipping by standard mail to Europe is most cheaper!

How to make rivets(5)

With help from "MikeGrant Rivet Decals"

No set number - universal usable (1/87 or smaller scale ?? ) - (contains 2 sheets - size A5 14,8 x 21cm) - (noted price 2019 around 8,50 Euro)

Warning!

The rivet decals from MikeGrant are small en not convex but flat and must be applied to the paint layer and will then simulate rivets as such - not recommended)

.

.

Description:

Finely printed rows of rivets, including useful shapes and arced sections for curved surfaces. Two sheets in a pack, one in dark grey (looks great on a black airframe) and one in silver

For more information and/or ordering:

Website MikeGrant

Website MikeGrant

Review MikeGrant Rivetdecals on Modelling Madness

Review MikeGrant Rivetdecals on Modelling Madness

Review MicroMark & MikeGrant Rivetdecals on IMPS.nl

Review MicroMark & MikeGrant Rivetdecals on IMPS.nl

How to make rivets(6)

With help from "MaxModelDecal"

set M711 - Resin thick decal. Trim the decal paper and use water to apply on the model. Prespaced rivets round head for 87th scale - (noted price 2019 around 7,50 Euro)

.

.

For more information and ordering:

Website MaxModelDecal

Website MaxModelDecal

How to make rivets(7)

With help from "HGW Decal" from Czech

Sets HGW722011, HGW722012, HGW722013 - (size 20x7 cm) - (noted price 2019 around 4,50 Euro each)

.

.

For more information and ordering:

Website HGW Decals

Website HGW Decals

For decal instructions:

Website HGW Decals

Website HGW Decals

Instructions on YouTube:

Website HGW Decals

Website HGW Decals

Review HGW-321014: zilver 1/32 klinknagels by Kevin Futter on (www.largescaleplanes.com):

Website Largescaleplans

Website Largescaleplans

How to make rivets(8)

With help from "Decals4all"

By this manufacturer you can order your own "Decal sheets" with printed rivets in the dimensions & distances you want. - (Size A6 - 14,8x10,5cm) - (noted price 2019 around 15 Euro each)

.

.

For more information and ordering:

Website Decals4all

Website Decals4all

How to make rivets, nuts and bolts, zimmeritt etc.(9)

With help from special tools from "Brain Factory, Japan"

Website in Japanese Language.

Information from John O'Reily - Japan

Itís actually a heat pen, that can be fitted with various shaped bits.

The material used to make the various shapes is old sprue. The sprue is heat flattened. Then using the small square of Teflon as a base to rest

your sprue material, you push the heated bit through the sprue material. Drag it away from the base sprue material. Remove any excess material

using fine tweezers. Then using the Rivet Ruler, place in desired position. It doesnít say but I gather it heat bonds to the plastic.

From the article I gather that the smallest rivet you can make is 0.3mm

.

.

.

For information, ordering etc, visit the website and look around what is possible:

Website Brain Factory, Japan

Website Brain Factory, Japan

Website Brain Factory "Panzer Graph Magazin"

Website Brain Factory "Panzer Graph Magazin"

How to make rivets, nuts and bolts, etc. with information from other websites

How to soldering in the small scale, by Marc Mercier on OTW

"Soldering made easy", article by Marc Mercier.

"Soldering made easy", article by Marc Mercier.

How to copy small parts with help from Blue Stuff - (Reusable moulding materials)

"Green Stuff World" - Reusable moulding material and other products and tools for all levels.

"Green Stuff World" - Reusable moulding material and other products and tools for all levels.

"You Tube" - Instruction movies about "How to work with Blue Stuff"

"You Tube" - Instruction movies about "How to work with Blue Stuff"

Dear Visitors:

My apologies that I have linked the information below to other web-sites. But, I can't give better information by myself.

The information about "Construction Techniques" is linked to the site from Simon Barnes & Doug Chaltry, the owners of the site "On The Way", one of the best Military Modeling Websites of the world.

Construction Techniques

Specialised in 1/72 small scale modelling. The best site for information about the military small scale!!!

Specialised in 1/72 small scale modelling. The best site for information about the military small scale!!!

How to apply decals correct

1. Basic methode with water.

Cut out from the sheet the necessary decals, plunge them into a vessel with pure water for about 0,5 minute, apply the decals on the kit, letting them

slide from the paper. For a better adhesion, press them by means of clean rag.

2. White glue methode.

Place a drop of white glue on a plastic plate, added some water, mixed it with a wooden stick and placed a drop of such solution on the painted

surface of the kit. White glue drys giving transparent film which fixes decal and solves a problem of excessive air under the decal (that is the

air that gives silvering effect to the decal).

3. Alcohol methode

Try some pure alcohol (ethyl or isopropyl). Alcohol can dissolve varnish layer of the decal and weld it to the paint (this method works well

with nitro enamels)

4. With Microscale products

Microscale liquids for decals. Set is used to improve decal adhesion (this liquid is based on acetic acid according to its odor) and is useless

in our case. Sol softens varnish film of the decal and works well on the uneven surfaces. Can help in our case. But be very-very careful applying

Sol. Decal becomes very elastic and can be easily over-elongated. I used ear sticks to apply Sol. It prove to be very useful in some cases.

How to apply decals with help from Micro Set and Micro Sol

Links to www.youtube.com and shows you how to apply decals with MicroScale products

Applying decals with solution, by Dream Knight (English Language)

Applying decals with solution, by Dream Knight (English Language)

Applying decals with Gloss coat the surface first (English Language)

Applying decals with Gloss coat the surface first (English Language)

5. With Future Acrylic Floor polish (Pledge with future shine e.o.)

Future is magical gloss varnish widely used by aircraft modellers. You should spray Your kit with Future, let this film dry, then apply Your decals,

then new lay of Future which should dry and only then You may use dull coat.

Link to "www.swannysmodels.com/TheCompleteFuture.html" and shows you information about Future, by Matt Swan

Shows most of the product names from Future over the world and gives information about working with Future (English Language)

Shows most of the product names from Future over the world and gives information about working with Future (English Language)

6. Silvering of decals - use the Future Acrylic Floor polish methode

Decal "silvering" is air trapped under the decal. Gloss coat the surface first. If you don't want to gloss the whole model you can use Future

(or it's equivalent where you live) as a setting solution. Just pull the decal through a small puddle of it and apply it, the Future will fill

any voids in the flat paint and stop the silvering. For decals already applied try poking holes in the decal with a pin in the decal and

apply more solvent.

How to "gloss coat the surface first" with help from Future Acrylic Floorpolish

Link to www.youtube.com and shows you "how to gloss coat the surface first" with Future

Gloss coat the surface(English Language)

Gloss coat the surface(English Language)

How to know which paintcolors I have to use - Chart of Paint Colors - This page gives you color Charts from several paint manufacturers

How to "Weathering your Models", excellent weathering tutorials

ScaleModelMedic on "YOU TUBE" with several weathering tutorials

ScaleModelMedic on "YOU TUBE" with several weathering tutorials

HeresyBrush Blog about weathering(Several Languages)

HeresyBrush Blog about weathering(Several Languages)

AirBrush Technique

The link is linked to www.scaleworkshop.com, the website from Testor Scale Workshop, with in the Workshop a lot of "airbrush technics" instruction video's from Brett Green and Chris Wauchop

Testors Small Scale Website (English Language)

Testors Small Scale Website (English Language)

Dry Brush Technique

This links below are linked to the website from T-izumi, from Japan

Website from T-Izumi, called "MINISUKE-YA" (Japanese Language - with a little English)

Website from T-Izumi, called "MINISUKE-YA" (Japanese Language - with a little English)

The pages below are translated from Japanese Language to English Language

- The camouflage painting(Form of halftone plate camouflage) - part 1

- The camouflage painting(Form of halftone plate camouflage) - part 1

- The camouflage painting (Two colors of painting) - part 2

- The camouflage painting (Two colors of painting) - part 2

- The camouflage painting (Three colors of painting) - part 3

- The camouflage painting (Three colors of painting) - part 3

- Weathering paint - part 4

- Weathering paint - part 4

The information about "casting your own models" is linked to the web-site from Hans van Oerle. A small nice site with good information

Casting Technique 1:

Hans van Oerle from the Netherlands specialised in 1/72-76 small scale modelling.

Hans van Oerle from the Netherlands specialised in 1/72-76 small scale modelling.

The information about "Casting" from Stephen Brezinski is linked to the web-site from "Missing Lynx". A very nice site with a lot of information and discussion group

Casting Techniques 2:

Missing-Lynx, a very nice site with a lot of information.

Missing-Lynx, a very nice site with a lot of information.

Hints en Tips in het Nederlands (Dutch Language)

Voor de Nederlandse Modelbouwers vond ik op de site van IPMS Nederland, een prachtige pagina met modelbouw adviezen in het Nederlands. (En dat leest voor ons altijd nog gemakkelijker)

Hints en Tips van IPMS Nederland.

Hints en Tips van IPMS Nederland.

Website van IPMS Nederland.

Website van IPMS Nederland.

Gebruik Future Floor Polish / Pledge Parket Plus

Modelbrouwers website.

Modelbrouwers website.

Email to HenkofHolland:

Note:

This website is an extension of my modeling hobby and serves to inform only.

It is NOT possible to order merchandise directly from me.

I do not own a (web-)shop. You will find some reliable vendors in the "links" page.

E-mail to HenkofHolland

E-mail to HenkofHolland

Note: To become a valid e-mail address, replace in email address (at) with @

Evergreen Scale Models Website

Evergreen Scale Models Website SlatersPlastiKard Website (Railway Products)

SlatersPlastiKard Website (Railway Products) Milliput Epoxy Putty Website

Milliput Epoxy Putty Website "MiniAfv" Blogspot

"MiniAfv" Blogspot "MiniAfv" Blogspot

"MiniAfv" Blogspot "MiniAfv" Blogspot

"MiniAfv" Blogspot "MiniAfv" Blogspot

"MiniAfv" Blogspot

Website Archer-Transfers

Website Archer-Transfers

Website MicroMark

Website MicroMark Comperison MicroMark (O-scale) rivet sheet with Archer Transfer 88001 - (YouTube)

Comperison MicroMark (O-scale) rivet sheet with Archer Transfer 88001 - (YouTube)

Website MikeGrant

Website MikeGrant Review MikeGrant Rivetdecals on Modelling Madness

Review MikeGrant Rivetdecals on Modelling Madness Review MicroMark & MikeGrant Rivetdecals on IMPS.nl

Review MicroMark & MikeGrant Rivetdecals on IMPS.nl

Website MaxModelDecal

Website MaxModelDecal

Website HGW Decals

Website HGW Decals Website HGW Decals

Website HGW Decals Website HGW Decals

Website HGW Decals Website Largescaleplans

Website Largescaleplans

Website Decals4all

Website Decals4all

Website Brain Factory, Japan

Website Brain Factory, Japan Website Brain Factory "Panzer Graph Magazin"

Website Brain Factory "Panzer Graph Magazin" Specialised in 1/72 small scale modelling. The best site for information about the military small scale!!!

Specialised in 1/72 small scale modelling. The best site for information about the military small scale!!!

Shows most of the product names from Future over the world and gives information about working with Future (English Language)

Shows most of the product names from Future over the world and gives information about working with Future (English Language)

Hans van Oerle from the Netherlands specialised in 1/72-76 small scale modelling.

Hans van Oerle from the Netherlands specialised in 1/72-76 small scale modelling.

Missing-Lynx, a very nice site with a lot of information.

Missing-Lynx, a very nice site with a lot of information.

Hints en Tips van IPMS Nederland.

Hints en Tips van IPMS Nederland.